Hobbyist painting only a few times a year but i would like the safety and cleanliness of a booth for painting and sanding.

Spray booth air flow calculation.

This is the size of the fan needed.

The real issue with air flow in a spray paint booth is having adequate air.

For this example let s use 50 fpm.

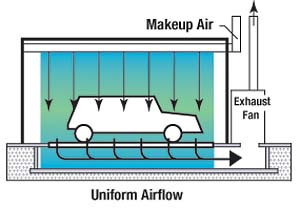

Controlling the paint booth air flow going into the booth with relation to the air being exhausted from the booth is critically important to maintain the proper flow of air over the item being painted and remove the over spray effectively.

Once you have measured the air flow you will want to see what the original design specification for your paint booth airflow was.

One hundred feet per minute is the guideline for air movement in the booth area.

Multiply the booth s face area by 100 feet per minute to achieve cfm.

Using the example from above 80 square feet multiplied by 100 feet per minute equals 8 000 cfm.

High and goes back.

If a downdraft paint booth is 16 feet wide and 14 feet tall typical air velocity in the booth would be 50 to 100 fpm.

Discover the 4 basic types of booth airflow designs that best apply to your paint finishing requirements just select a crossdraft or downdraft airflow design below and learn the fundamentals of the airflow and filtration system.

Fans to push and pull the air being pushed in and pulled out are done with two types of fans.

Additionally the closer you are to the filterbank the faster the fpm will be in most booths.

Why paint booth cfm is important paint booths are designed to meet a minimum air flow requirement to be compliant with national codes that govern spray booths.

Important codes that paint booths comply with include national fire code 1 nfpa 33 osha and a few others.

Dividing the flow rate by the volume 32 000 8 960 gives 3 5 air changes per minute.

The calculations of a booth are based upon cubic feet of air in the booth and cfm of the exhaust system.

The total flow through the booth 16 x 40 x 50 would be 32 000 cfm.

By ron joseph.

Hello i have a math and set up question.

Running this spray booth for twenty minutes requires 262 080 cubic feet of available air.

For a good overview of all paint booth code compliance check out this article.

Assume a modified down draft no pit and the booth is 16 ft.

Ask the expert question and answer archive.

Wide and 12 ft.

Paint booth air flow designs.

The airflow of the fmp in the work area is a direct result of how the airstream flows through the work area.

I am planning a spray booth in my small barn shop.

Typical paint booth air flow values can be read about here or just remember typically a cross draft paint booth will have air flow of about 100 feet per minute based on the width and height of the booth a downdraft will have air flow of about 50 feet per minute.

I have tried to figure this out without having to post but i remain confused.