The ship s sonar array is guarded by the dome and minimizes the interference in sound transmission and reception which empowers the diagnosis and classification.

Sonar dome rubber window manual.

The sonar dome rubber window sdrw 1 technical manual has been prepared to provide guidance to both naval and commercial activities which install repair groom or maintain sonar domes and their associated pressurization systems.

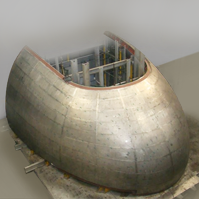

Figure 6 shows the plys or layers of a surface ship rubber sonar dome.

Navsea sponsored training e g sonar dome rubber window sdrw.

Thus the name sonar dome rubber window.

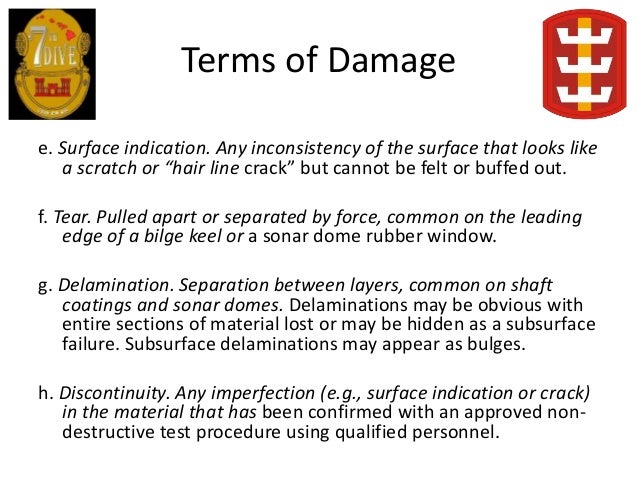

The most common repair is patching the rubber window.

1 discharged overboard if the vessel is waterborne or 2 collected for proper management ashore if the vessel is in drydock.

2 2 releases to the environment there are two sonar dome discharges discharges of the water from the interior of sonar domes and external discharges.

Underwater ship husbandry manual navsea s0600 aa pro 170 1.

This type of sonar dome has been.

The first five ship classes included are uss ticonderoga cg 47 uss nimitz cvn 68 uss spruance dd.

The 19 ton bow domes are made with a rubber wire reinforced material that has nearly the same density of seawater.

These domes are installed on cruisers and destroyer class type size.

The sonar dome rubber window has been manufactured at the company s facility in jacksonville florida us to the us navy.

This letter promulgates chapter 17 of the underwater ship husbandry manual.

A diver removes loose rubber prepares the edges to receive a patch and affixes a rubber patch with an amine polymer.

Sonar dome rubber window is a transparent housing that circumambience the sonar transducer array on the bow of destroyers and cruisers forging the sonar s sensor system.

Navy for over 35 years.

This information will be of value to the fleet because the performance of sonar domes.

The water emptied from the sonar dome interior is.

Epp also provides field services for the installation inspection and repair of its sonar domes in support of customers.

Sonar dome design a dome design is always a compromise between sonar acoustic performance with respect to dome material material thickness dome shape position of the array inside the dome baffle sonar s out put power external noise and anechoic and mechanical strength to withstand high slamming conditions at sea.

This chapter is the first document to detail specific inspection procedures for each ship class.

Minor repairs to the exterior of rubber sonar domes can be accomplished by divers.